» Separation of mill stock(semolina) by size and specific weight

» Grinding Section

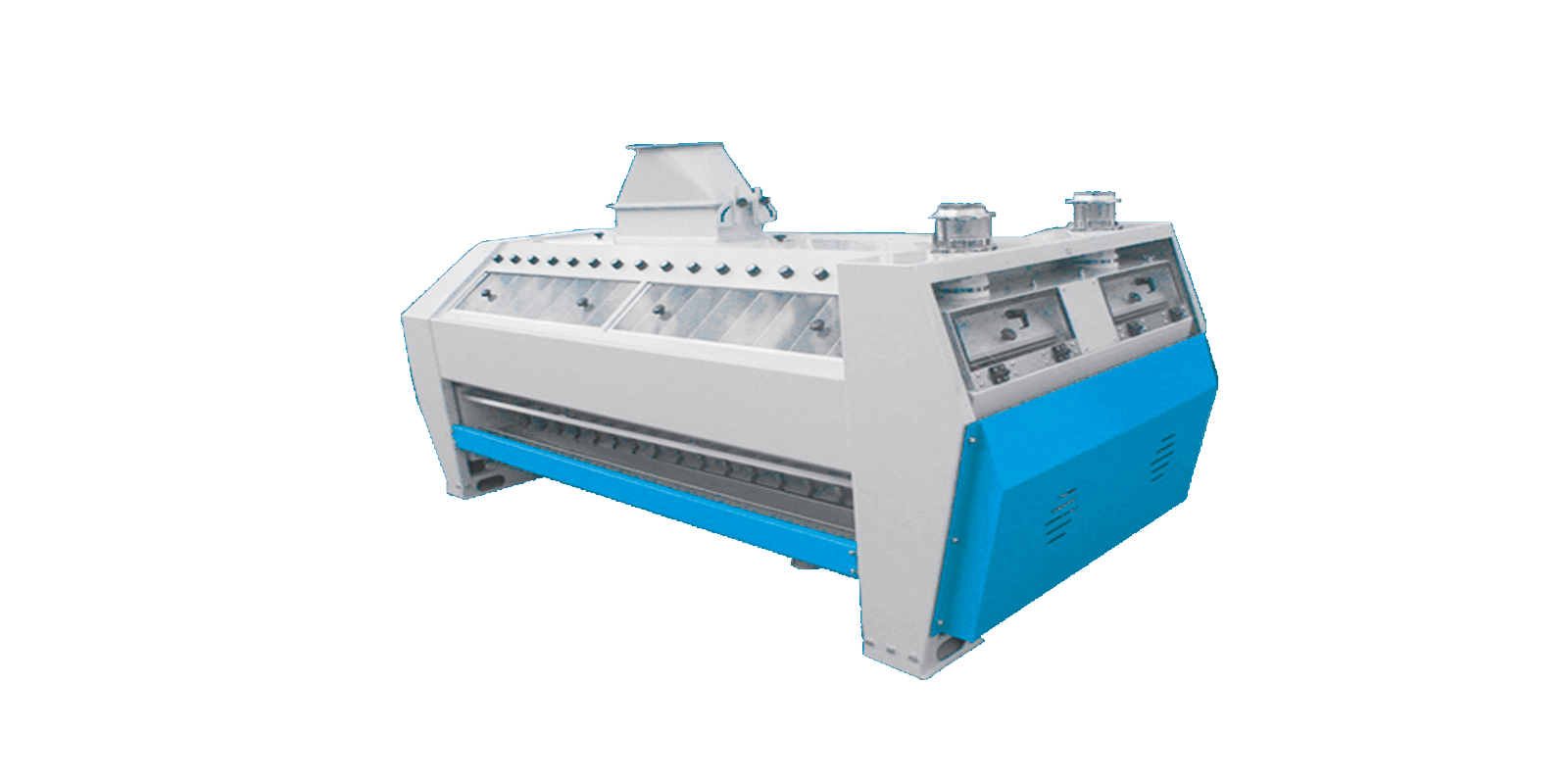

» Machine frame with hood

» Sieve box (oscillating sieve)

» Collection channels for the throughs

» Deflection gates

» Hollow rubber springs

» High stratification and purification effect by use of suction air

» High effciency for end producy yield

» Silent operation

» The sieving process can be done by a 2 deck sieve

» Uniform air flow

» Easy sieve removal

» Sieve illumination(explosion proof)

» Available aspiration connection

» Plexiglass sight

» Re-tensionable sieve covers

» Adjusting flaps for throughs

» Adjusting flaps for overtails

» Adjustable speed of cleaning system

» Air regulating valves & Aerodynamic air duct

» Use of larger screens and thus getting more output is possible

» Access from all sides

» Available brush cleaning device

» Wear protection in feed box

» Drive hollow rubber supports

» High degree of internal sanitation

» Easy maintenance, user friendly

» Easy cleaning

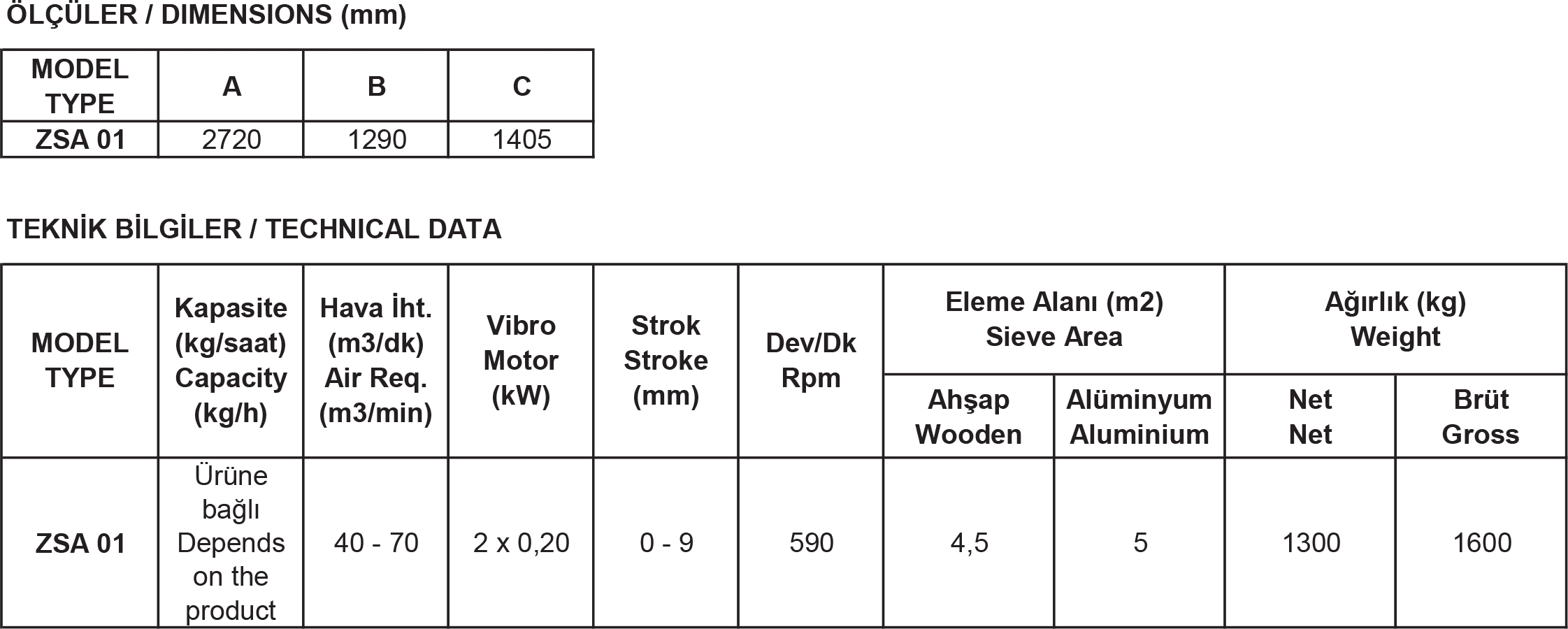

» Two counter rotating vibromotors are fastened directly to the sieve box

» Two maintenance-free eccentric motors serve as drive for both sieve box and the collection channels

*SIMCO MACHINE reserves the right to change the design and technical specifications of the machines without prior notice.

*SIMCO MACHINE reserves the right to change the design and technical specifications of the machines without prior notice.